advantages of CFD: In the dynamic realm of engineering and design, Computational Fluid Dynamics (CFD) has emerged as a transformative force. CFD, at its core, involves the simulation of fluid flow, heat transfer, and other related phenomena through advanced computational methods. Its significance reverberates across diverse industries, from aerospace to environmental engineering. In a nutshell, CFD grants engineers the ability to virtually model and analyze complex fluid behaviors, offering insights that were once confined to the physical realm. The following exploration delves into the myriad advantages that position CFD as a pivotal tool in the arsenal of modern engineering, facilitating a paradigm shift in the way we conceptualize and refine designs.

II. Speed and Efficiency

In the fast-paced landscape of product development, time is often a critical factor. CFD comes to the forefront, presenting a boon in terms of speed and efficiency. The traditional approach to testing and refining prototypes involves time-consuming physical experiments. Enter CFD, which allows engineers to rapidly analyze complex scenarios within a digital environment. This not only expedites the design process but also significantly reduces the time and costs associated with traditional prototyping.

The ability to iterate designs swiftly and assess their performance virtually provides a competitive edge to industries aiming to bring innovative products to market promptly. CFD’s contribution to speed and efficiency is not merely a convenience; it is a strategic advantage that aligns seamlessly with the demands of a fast-paced technological landscape.

III. Accuracy and Precision

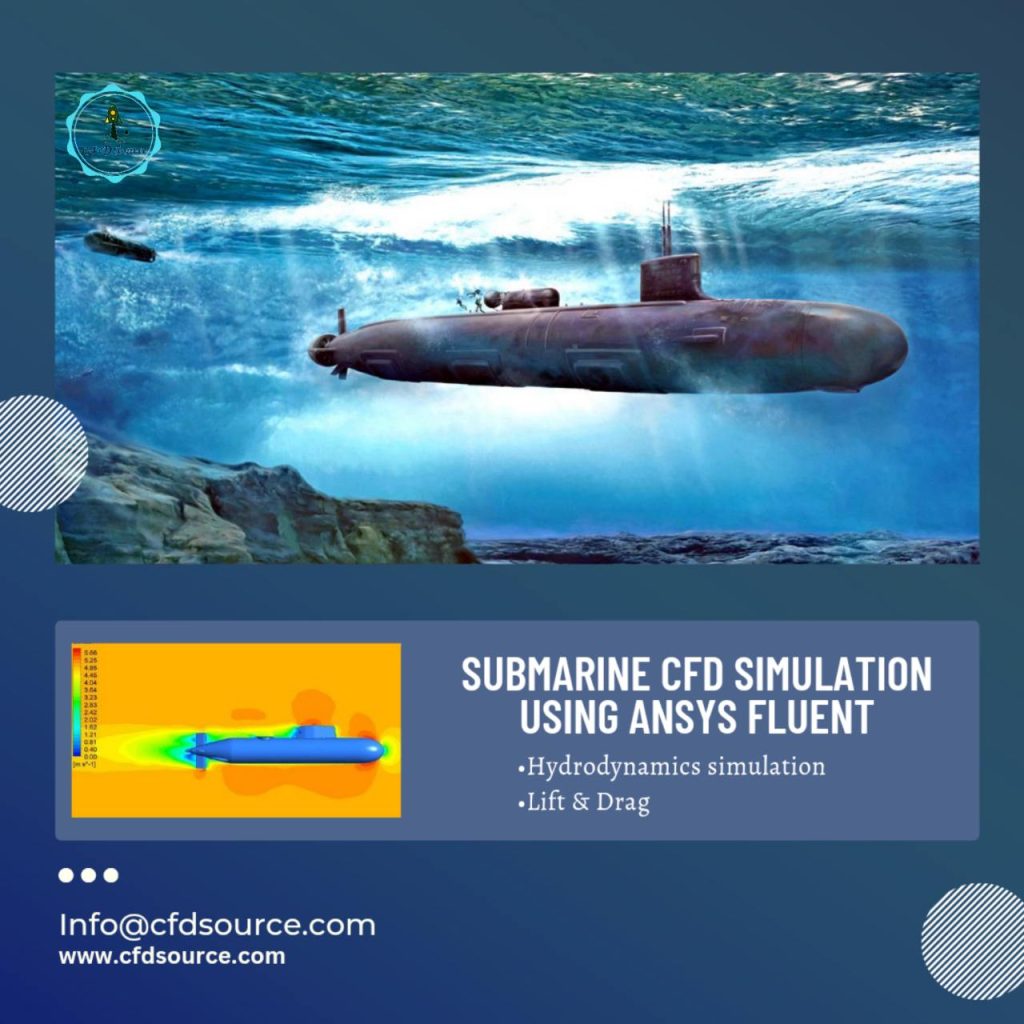

Precision in engineering is non-negotiable, and CFD stands as a beacon of accuracy in the realm of fluid dynamics simulations. The depth of understanding provided by CFD simulations is unparalleled, offering engineers a detailed and realistic depiction of fluid behaviors. The simulations are crafted to mimic real-world conditions, enabling a level of precision that transcends the limitations of physical testing.

This accuracy is not just a luxury but a necessity, particularly in industries where performance and reliability are paramount. As CFD models continue to evolve, so does their capacity to provide nuanced insights into complex fluid interactions. In essence, CFD transforms the design and decision-making process by offering a reliable and precise virtual testing ground.

IV. Risk Mitigation

In the intricate dance of product development, risks lurk at every turn. Identifying and mitigating these risks early in the process is a strategic imperative, and here’s where CFD shines. By allowing engineers to identify potential issues through virtual simulations, CFD acts as a powerful risk mitigation tool. Imagine being able to foresee and rectify flaws in a design before it even reaches the physical prototype stage. This is precisely what CFD enables – a proactive approach to risk management.

The simulations not only highlight potential pitfalls but also empower decision-makers with data-backed insights, fostering a risk-averse culture within the development process. The result is a more robust and reliable final product, grounded in a thorough understanding of potential challenges and their preemptive solutions. CFD, in essence, transforms uncertainty into a manageable variable in the complex equation of product development.

V. Design Optimization

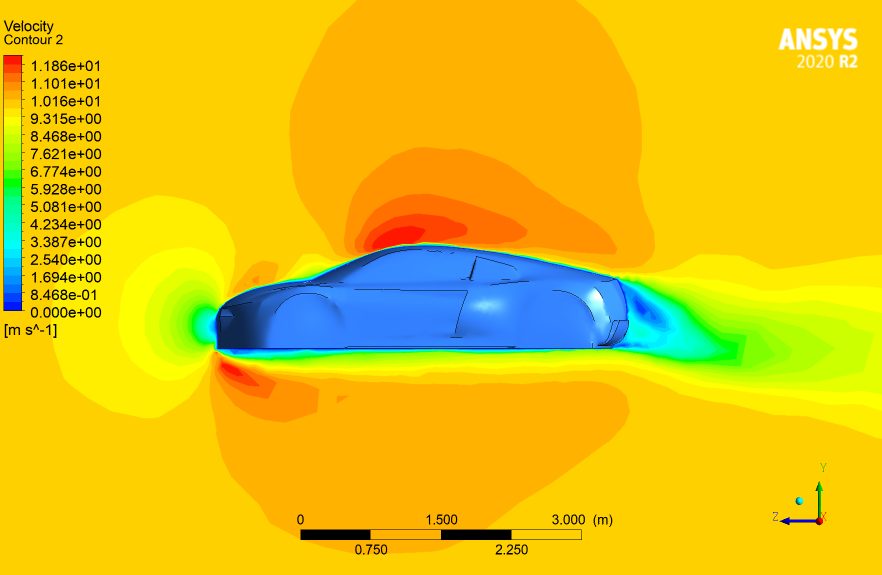

In the intricate tapestry of product development, the quest for optimal design is an ongoing journey. Computational Fluid Dynamics (CFD) emerges as a guiding light in this pursuit, facilitating a paradigm shift in design optimization. Through CFD, engineers can engage in iterative processes, fine-tuning designs with a precision that was once inconceivable. The ability to virtually test and refine products based on fluid dynamics simulations ensures that each iteration brings the design closer to its optimal performance. Whether in the aerospace industry, where aerodynamics play a pivotal role, or in automotive engineering, where fuel efficiency is paramount, CFD provides a virtual playground for designers. The result is not just aesthetically pleasing designs but products that excel in functionality and efficiency, setting a new standard for optimization in the competitive landscape.

VI. Flexibility in Modeling

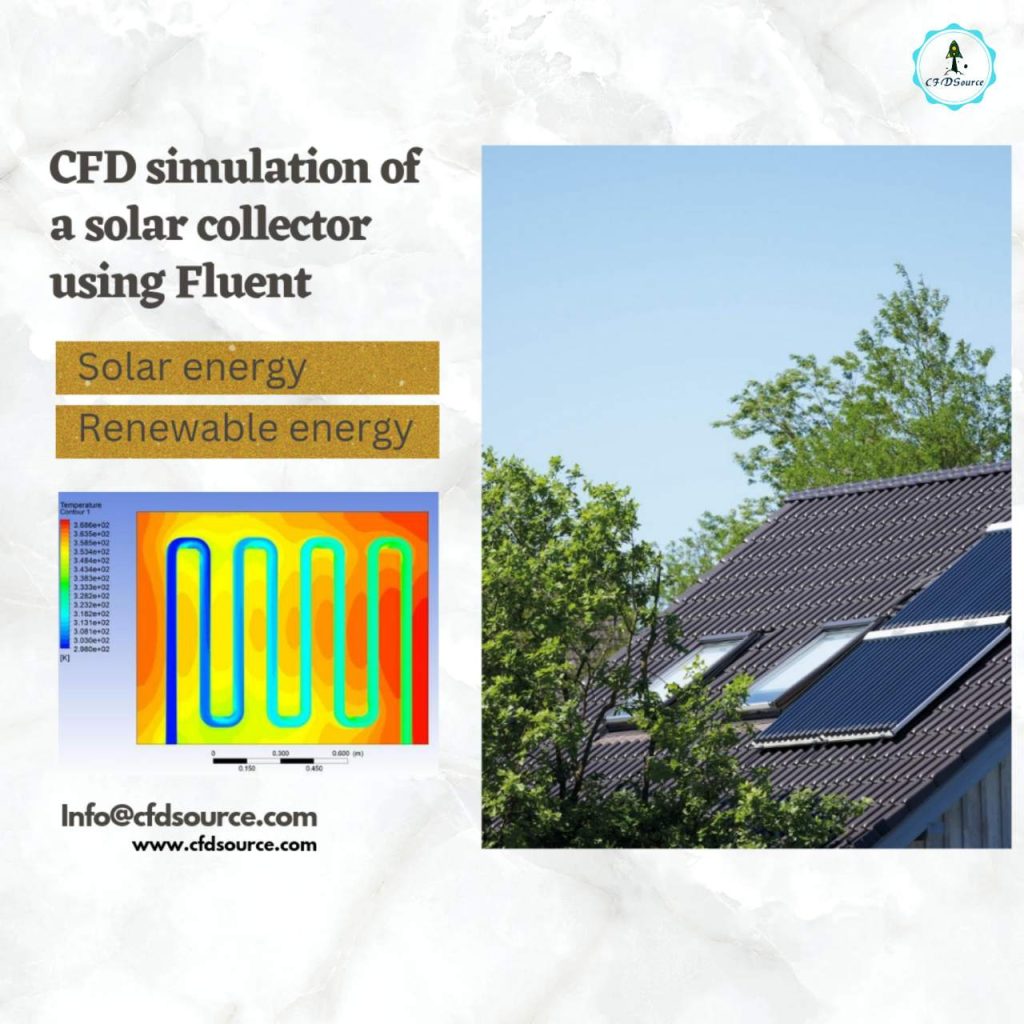

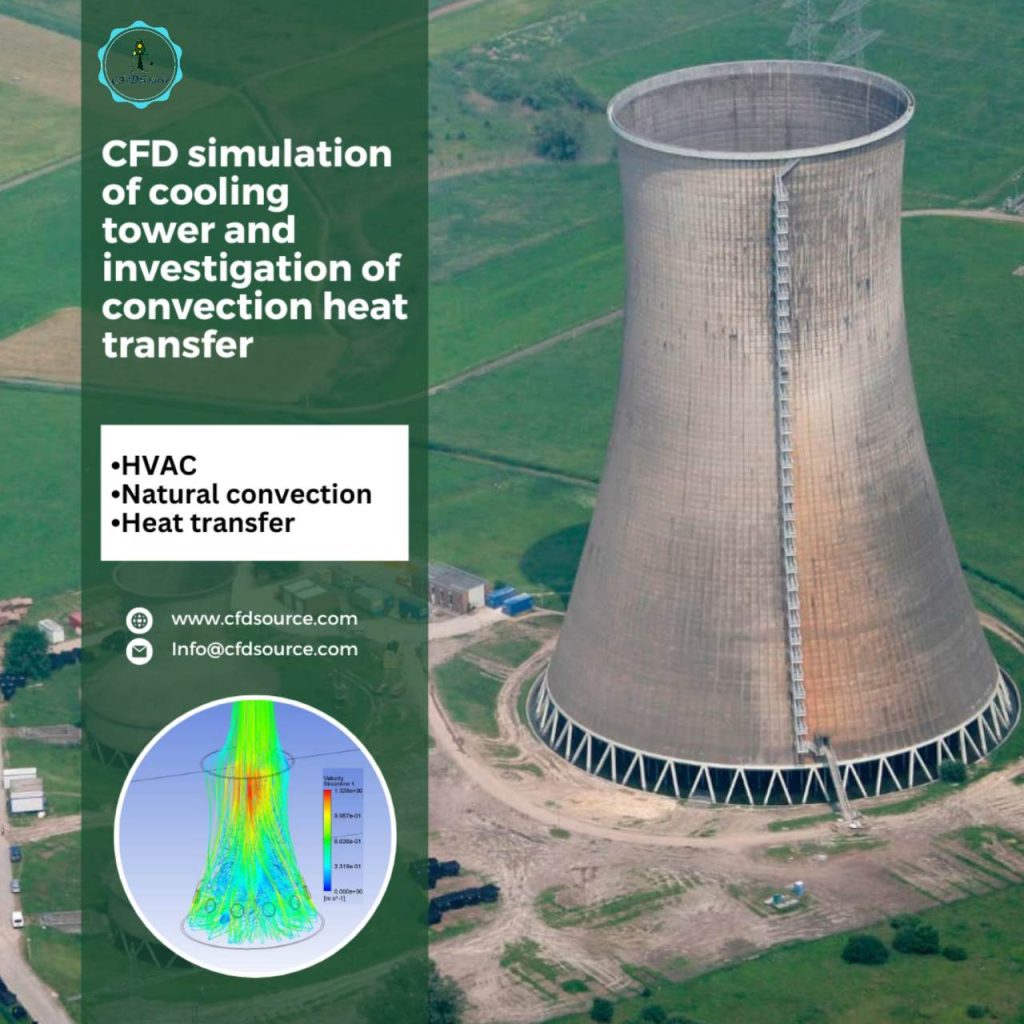

Versatility is the hallmark of any powerful tool, and Computational Fluid Dynamics (CFD) exemplifies this attribute in the realm of modeling. Its applications span a multitude of industries, adapting seamlessly to the unique challenges posed by each. The flexibility of CFD models allows engineers to simulate a wide range of fluid behaviors, from the airflow around an aircraft wing to the intricate dynamics within a combustion engine.

This adaptability is not confined to specific industries but extends to the ever-changing conditions within each sector. Whether it’s simulating the impact of environmental factors on a building’s design or optimizing the fluid flow in a biomedical device, CFD molds itself to the contours of diverse applications. The result is a tool that transcends boundaries, offering a universal solution for engineers navigating the complexities of fluid dynamics across industries.

VII. Resource Conservation

In an era where sustainability is a global imperative, Computational Fluid Dynamics (CFD) emerges as a silent champion of resource conservation. Traditional product development pathways often involve the creation of numerous physical prototypes, consuming materials and energy at each iteration. CFD, with its virtual testing capabilities, disrupts this pattern. By minimizing the need for physical prototypes, it directly contributes to resource conservation.

The environmental impact of reduced prototyping goes beyond material savings; it translates into a significant reduction in waste and energy consumption. As industries globally shift towards eco-friendly practices, CFD becomes a linchpin in achieving sustainability goals. Its role in resource conservation aligns seamlessly with the ethos of responsible engineering, ushering in a new era where innovation goes hand in hand with environmental stewardship.

VIII. Competitive Edge

In the relentless arena of market competition, gaining a competitive edge is not just a strategic advantage; it’s a survival imperative. Computational Fluid Dynamics (CFD) emerges as a formidable ally in this pursuit, offering a pathway to innovation and adaptation. Businesses that leverage CFD find themselves at the forefront of technological advancement, pushing the boundaries of what’s possible in product development.

The speed, accuracy, and efficiency conferred by CFD provide a unique advantage, enabling companies to bring cutting-edge products to market swiftly. Staying ahead in the market is not just about meeting current demands but anticipating future trends. CFD, with its predictive capabilities and versatility, positions businesses to be proactive rather than reactive. In the dynamic landscape of industry competition, CFD is the compass that guides enterprises towards not just survival but sustained success.

IX. Case Studies

The real litmus test for any transformative technology lies in its practical application and tangible outcomes. In the world of Computational Fluid Dynamics (CFD), the proof is not just in the theory but in the real-world case studies that underscore its efficacy. Examining successful implementations across industries reveals the depth of impact that CFD can have.

From optimizing the aerodynamics of race cars to enhancing the efficiency of HVAC systems in commercial buildings, CFD has left an indelible mark on diverse sectors. Case studies serve as beacons of success, showcasing how CFD has been instrumental in overcoming specific challenges and achieving measurable improvements. These real-world narratives not only validate the theoretical advantages of CFD but also provide a roadmap for other industries looking to harness its potential for transformative outcomes.

X. Challenges and Solutions

No transformative technology is without its challenges, and Computational Fluid Dynamics (CFD) is no exception. Acknowledging and addressing these challenges head-on is essential for the seamless integration of CFD into engineering workflows. Common concerns may include the need for skilled professionals to operate CFD software effectively and the computational limitations that can arise with complex simulations.

However, these challenges are not insurmountable roadblocks; they are opportunities for innovation and improvement. Solutions range from investing in training programs to nurture a skilled workforce to advancements in hardware and software that address computational bottlenecks. By openly acknowledging challenges and actively seeking solutions, the engineering community can ensure that CFD continues to evolve as a reliable and effective tool, unlocking its full potential for diverse applications.

XI. Future Trends

advantages of CFD: The field of Computational Fluid Dynamics (CFD) is dynamic, with ongoing advancements and innovations shaping its future trajectory. As technology evolves, so does the landscape of possibilities for CFD applications. Emerging trends point towards more sophisticated simulation capabilities, increased automation in the modeling process, and a seamless integration of CFD with other simulation tools.

The development of hybrid models that combine physics-based and data-driven approaches is on the horizon, promising more accurate and efficient simulations. Additionally, the democratization of CFD, with user-friendly interfaces and cloud-based solutions, is making this powerful tool accessible to a broader audience. The future of CFD holds the promise of pushing the boundaries of what is conceivable, with applications extending beyond traditional engineering to fields such as medicine and climate science.

XII. Industry Recommendations

As Computational Fluid Dynamics (CFD) continues to gain prominence, industry stakeholders are faced with the task of effective integration into existing workflows. Strategic planning and thoughtful implementation are crucial for maximizing the benefits of CFD. Industry recommendations encompass a spectrum of considerations, from devising effective integration strategies to prioritizing training and skill development among professionals.

The seamless integration of CFD requires a collaborative approach, involving not only engineers but also decision-makers and stakeholders. Recommendations also extend to establishing a culture of continuous improvement, where feedback from CFD simulations informs iterative design processes. By heeding these industry recommendations, businesses can position themselves to harness the full potential of CFD, realizing tangible benefits in terms of efficiency, innovation, and competitive advantage.

XII. Industry Recommendations

The integration of Computational Fluid Dynamics (CFD) into industry practices demands a strategic approach and thoughtful recommendations. First and foremost, devising effective integration strategies is crucial. This involves understanding the specific needs and challenges of the industry in question, aligning CFD applications with existing workflows, and ensuring a seamless transition. Training and skill development play an equally pivotal role. Investing in the education and proficiency of professionals who will operate CFD software is essential for realizing its full potential.

Industry leaders should prioritize creating a workforce adept at leveraging CFD to enhance product design, streamline processes, and make informed decisions. Additionally, fostering a culture of continuous improvement is paramount. CFD is not a one-time solution but an evolving tool. Regular feedback loops from CFD simulations should inform iterative design processes, ensuring a dynamic and responsive approach to engineering challenges. By adhering to these industry recommendations, businesses can position themselves at the forefront of innovation and efficiency.

XIII. Client Testimonials

The true measure of success for any technology lies in the experiences of those who have embraced it. Client testimonials in the realm of Computational Fluid Dynamics (CFD) provide invaluable insights into the real-world impact of this transformative tool. Positive experiences shared by clients across industries underscore the practical advantages of integrating CFD into engineering workflows. These testimonials narrate stories of enhanced design precision, accelerated product development cycles, and, ultimately, improved business outcomes. Whether it’s an aerospace company optimizing aircraft aerodynamics or an automotive manufacturer fine-tuning fuel efficiency, client testimonials serve as testament to the tangible benefits that CFD brings to the table. They resonate as voices of authority, offering a compelling narrative for businesses contemplating the adoption of CFD in their quest for engineering excellence.

XIV. Expert Opinions

In the dynamic field of Computational Fluid Dynamics (CFD), expert opinions carry substantial weight. Insights from specialists who have dedicated their careers to mastering the intricacies of fluid dynamics offer a unique perspective. These experts delve into the nuances of CFD applications, highlighting best practices, potential challenges, and the evolving landscape of the technology. Their opinions guide industry professionals, providing a roadmap for effective implementation and maximizing the benefits of CFD. Recognized authorities in the field, through their evaluations and endorsements, contribute to the credibility of CFD as a transformative tool. As the technology advances, expert opinions become beacons of knowledge, guiding both seasoned professionals and emerging talents toward a deeper understanding of CFD’s potential and its evolving role in shaping the future of engineering.

XV. Conclusion

advantages of CFD: In conclusion, the advantages of Computational Fluid Dynamics (CFD) are not merely theoretical; they are the bedrock of a new era in engineering and design. From the speed and efficiency it brings to the precision it affords, CFD stands as a catalyst for innovation across industries. The risk mitigation capabilities, design optimization potential, and flexibility in modeling further underscore its transformative impact. As evidenced by real-world case studies and the recommendations of industry experts, CFD is not just a tool but a strategic asset for businesses aiming to stay ahead in the competitive landscape. The future trends in CFD point towards continued evolution and broader accessibility, promising even more profound applications. As businesses navigate the challenges and seize the opportunities presented by CFD, they position themselves not only for success but for sustained excellence in the dynamic world of engineering and design.