1. Introduction

CFD analysis of wind turbine: Wind energy, harnessed through wind turbines, has emerged as a key player in the world of renewable energy. The ever-increasing demand for clean and sustainable power sources has driven the rapid development of wind turbine technology. Wind turbines are ingeniously designed machines that capture the kinetic energy of wind and convert it into electricity. Their significance in the global shift toward cleaner energy sources cannot be overstated. In this context, the role of Computational Fluid Dynamics (CFD) has become paramount.

CFD provides engineers and researchers with a powerful tool to analyze the behavior of air and other fluids around wind turbines, enabling them to optimize the design and enhance performance. It allows for comprehensive simulations and predictions, reducing the need for expensive physical prototypes and extensive testing. This article delves into the world of wind turbines, CFD, and their symbiotic relationship in advancing the efficiency and sustainability of wind energy.

2. Understanding Wind Turbines

To grasp the significance of CFD analysis in wind turbine design, it’s crucial to understand the two primary types of wind turbines – horizontal-axis wind turbines (HAWT) and vertical-axis wind turbines (VAWT). Horizontal-axis wind turbines, characterized by their tall, slender towers and rotating blades, are the more prevalent design. They are often used in large wind farms, dotting landscapes around the world. The rotational movement of their blades is powered by the wind’s horizontal flow. In contrast, vertical-axis wind turbines are unique in that they have blades rotating around a vertical axis.

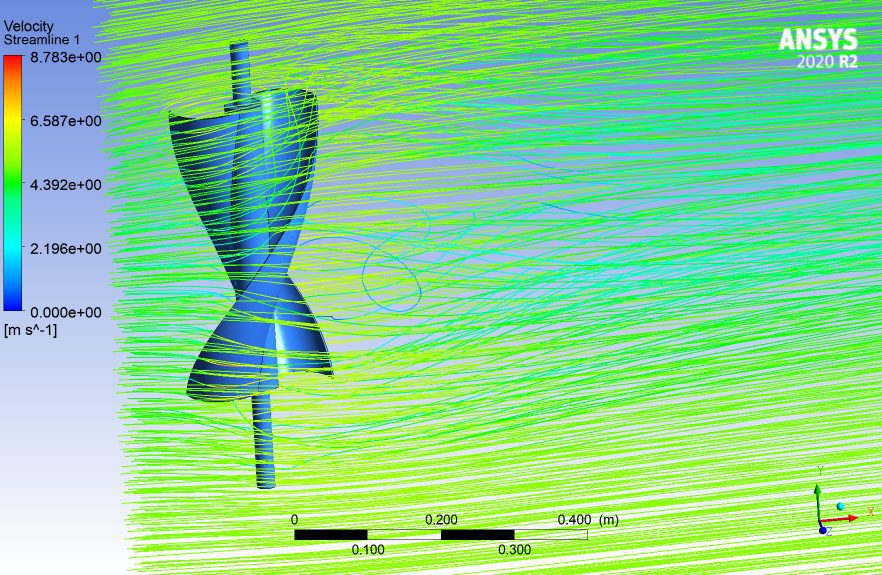

This design is particularly advantageous for certain applications where wind direction is variable. Vertical-axis turbines, often more compact and less visually obtrusive, are commonly used in smaller-scale installations or where aesthetics are a significant concern. Understanding the differences between these two turbine types is crucial as it helps determine the most suitable design for a specific location and purpose. CFD analysis plays a critical role in optimizing both HAWTs and VAWTs, ensuring they capture the maximum energy potential from the wind.

3. Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics, abbreviated as CFD, is a powerful simulation technique that facilitates the analysis of how fluids, such as air, behave around objects or within a specific environment. In the context of wind turbines, CFD is indispensable for understanding and predicting the flow of air and its interaction with various turbine components. This technology allows engineers to virtually recreate the complex aerodynamic conditions that turbines face, helping them make informed design choices and optimize performance.

CFD’s applications extend well beyond wind energy; it is widely used in aerospace, automotive design, and various other industries where fluid dynamics are a significant factor. The core principle behind CFD is the numerical solution of the Navier-Stokes equations, which describe the motion of fluids. These equations are solved iteratively across the computational domain to simulate fluid behavior. With ever-advancing computer processing power, CFD has become an essential tool for wind turbine design and analysis.

4. Importance of CFD in Wind Turbine Design

Wind turbine design is a multidisciplinary endeavor that requires a deep understanding of various factors, including aerodynamics, materials science, and mechanical engineering. CFD serves as a bridge between these disciplines, allowing engineers and researchers to gain valuable insights into how a wind turbine interacts with the surrounding air. The importance of CFD in wind turbine design can hardly be overstated. It facilitates the evaluation and optimization of turbine performance in a cost-effective and time-efficient manner.

Traditionally, the development of wind turbines involved extensive wind tunnel testing, which was not only expensive but also limited in terms of the data it could provide. CFD has revolutionized this process by enabling detailed simulations that capture a wide range of operating conditions and environmental factors. This has accelerated the development of more efficient and reliable wind turbines, making wind energy an increasingly viable and attractive source of sustainable power. Furthermore, CFD empowers engineers to explore innovative designs and strategies for harnessing wind energy effectively, paving the way for a greener and more sustainable future.

5. The CFD Process

The CFD process is a well-structured methodology for simulating fluid dynamics, and it plays a pivotal role in optimizing wind turbine design. This process consists of three key stages: preprocessing, simulation, and post-processing. Preprocessing involves creating a detailed digital model of the wind turbine, including its blades, tower, nacelle, and other relevant components. Engineers define the simulation parameters, specifying factors like wind speed, direction, and environmental conditions. This step is crucial, as the accuracy of the digital model and the input parameters significantly influence the simulation’s reliability.

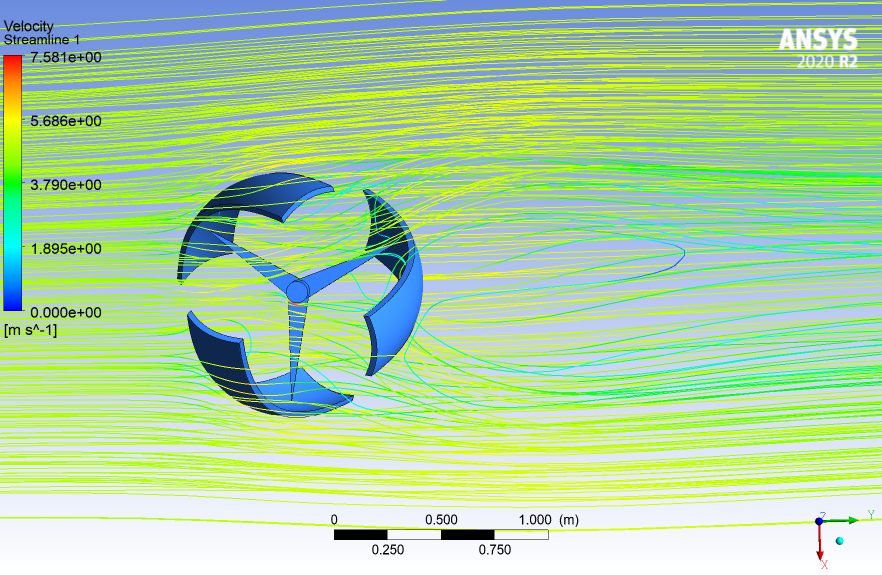

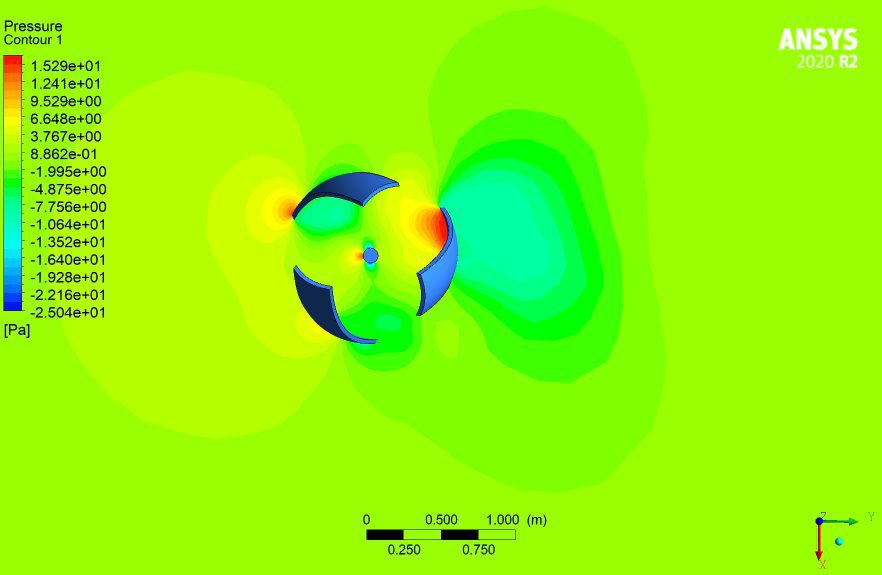

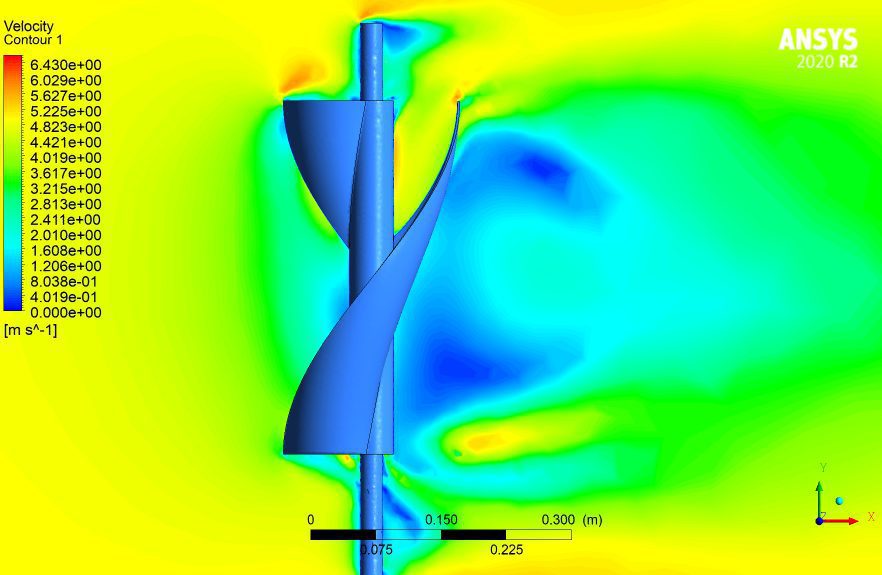

The simulation stage is the heart of CFD analysis. During this phase, complex mathematical equations governing fluid dynamics, such as the Navier-Stokes equations, are solved numerically. These equations describe the behavior of air as it flows over and around the wind turbine. The simulations are carried out over the defined computational domain, which includes the entire area where air interacts with the turbine. High-performance computing resources are employed to process the vast amount of data generated by these simulations. Engineers can explore different scenarios, allowing them to assess how the wind turbine performs under various conditions.

Post-processing is the final stage of the CFD process. In this step, engineers and researchers analyze the simulation results to extract meaningful insights. Visualization tools, graphs, and reports are often employed to make sense of the complex data. Post-processing allows for the assessment of aerodynamic efficiency, structural stresses, and other critical performance parameters. The information obtained from the CFD analysis guides engineers in making informed decisions about improving the wind turbine’s design, ensuring it operates at peak efficiency and durability. This structured CFD process revolutionizes wind turbine development, providing a reliable and cost-effective means to enhance their performance.

6. Factors Considered in CFD Analysis

When conducting CFD analysis for wind turbines, several crucial factors are considered to ensure the accuracy and comprehensiveness of the results. These factors include wind speed and direction, turbine blade design, and environmental conditions.

Wind speed and direction are foundational elements in CFD analysis. Engineers must accurately represent the wind’s behavior to understand how the turbine interacts with it. This includes modeling wind variability, as the wind speed and direction are rarely constant. By simulating various wind conditions, CFD analysis can reveal how a wind turbine’s performance varies under different scenarios, enabling engineers to design turbines that are effective across a range of environmental conditions.

Turbine blade design plays a central role in the efficiency of a wind turbine. The shape, size, and pitch of the blades significantly impact how much wind energy can be captured. CFD allows engineers to study the aerodynamics of different blade designs, optimizing their shape to maximize energy capture while minimizing drag. This fine-tuning of blade design is critical for achieving the highest possible energy output from the wind turbine.

Environmental conditions are another important consideration. CFD analysis takes into account factors like temperature, humidity, and turbulence in the atmosphere. These conditions can affect how air flows around the turbine and influence its performance. By including environmental factors in the simulations, engineers can develop wind turbines that are resilient and efficient in real-world conditions.

7. Benefits of CFD in Wind Turbine Development

The adoption of CFD in wind turbine development offers a multitude of benefits that positively impact both the industry and the environment. One of the most significant advantages is cost-effective design. Traditional wind turbine development required the construction of physical prototypes, which could be expensive and time-consuming. With CFD, the need for numerous physical tests is drastically reduced. Engineers can conduct extensive virtual testing, ensuring that only the most promising designs move forward for physical prototyping. This streamlined approach not only saves time but also reduces development costs.

Enhanced efficiency is another key benefit. CFD simulations allow for the fine-tuning of wind turbine designs to optimize performance. By analyzing the interaction of the turbine with varying wind conditions and refining blade designs, engineers can ensure that wind turbines capture as much energy as possible. This leads to increased power generation and greater overall efficiency, ultimately making wind energy more competitive and accessible.

Moreover, CFD analysis aligns with the goal of eco-friendly energy. Wind energy is a clean and renewable source of power, and CFD aids in making it even more sustainable. By optimizing wind turbine designs, CFD helps ensure that wind energy generation has a minimal environmental footprint. Wind turbines become more effective in harnessing wind power, reducing the need for fossil fuels and minimizing greenhouse gas emissions. This contribution to environmental sustainability makes CFD a valuable tool in addressing climate change and transitioning to greener energy sources.

8. Challenges in CFD Analysis

While CFD analysis has proven to be a transformative tool in wind turbine design, it comes with its set of challenges. The first significant challenge lies in creating complex, accurate digital models of wind turbines. These models must replicate the physical components of a turbine in great detail, including the blades, tower, nacelle, and other parts. The precision of the digital model directly impacts the accuracy of CFD results, and creating such detailed models can be a labor-intensive task. Additionally, ensuring that the simulation parameters, such as wind speed and direction, reflect real-world conditions is another challenge. Accurate representation of variable wind behavior is crucial for obtaining meaningful results.

Another challenge is the computational resources required for CFD simulations. Solving the Navier-Stokes equations for fluid dynamics involves complex mathematical operations. To achieve accurate results, high-performance computing clusters are often needed, and running simulations can be time-consuming and resource-intensive. This can pose financial and logistical challenges, especially for smaller organizations or research groups.

The integration of various aspects of wind turbine design, such as structural analysis and control system optimization, within the CFD framework is another ongoing challenge. Wind turbine design is a multidisciplinary endeavor, and successfully incorporating all relevant parameters and factors into a single simulation can be complex.

Despite these challenges, the potential benefits of CFD analysis make it a valuable investment. As technology advances and computing resources become more accessible, the wind energy industry is continually working to address these challenges and harness the full potential of CFD in wind turbine development.

9. Real-Life Applications

The application of CFD analysis in the development of wind turbines is far-reaching and extends into various sectors. In the aerospace industry, CFD is used to optimize the aerodynamics of aircraft, helping reduce fuel consumption and emissions. For automotive design, CFD analysis assists in improving the efficiency and performance of vehicles by optimizing their shape and reducing drag. In the realm of energy, CFD is a critical tool in the oil and gas industry for understanding fluid dynamics in reservoirs, pipelines, and refining processes. However, it is in the field of renewable energy, particularly wind energy, that CFD plays a pivotal role.

In the context of wind energy, CFD is applied not only in the design of individual turbines but also in the planning and optimization of entire wind farms. Wind farm layout, where multiple turbines are strategically positioned, is an essential aspect of maximizing energy production while minimizing interference between turbines. CFD aids in assessing wake effects, ensuring that downstream turbines receive adequate wind flow for optimal performance.

Additionally, CFD is instrumental in wind resource assessment. Engineers use CFD simulations to predict wind conditions at specific locations, helping decide where to install wind turbines for maximum energy capture. By simulating various scenarios and considering topographical features, CFD enables the selection of ideal locations for wind farm development.

Furthermore, CFD is used in the analysis of extreme weather conditions and their impact on wind turbines. Understanding how wind turbines perform during severe storms or high wind speeds is essential for safety and durability considerations.

10. Conclusion

In conclusion, Computational Fluid Dynamics (CFD) analysis plays a central role in the development and optimization of wind turbines. As the world’s demand for clean and sustainable energy continues to rise, the importance of harnessing wind energy effectively cannot be overstated. CFD enables engineers and researchers to conduct comprehensive simulations, evaluate wind turbine designs, and make informed decisions for performance improvement.

It eliminates the need for costly physical prototypes, streamlines the design process, and enhances the efficiency of wind turbines, ultimately contributing to a more sustainable and eco-friendly energy future. As technology continues to advance, the challenges of CFD analysis are being addressed, and its potential in wind turbine development is continually expanding. With the growing emphasis on renewable energy sources, CFD remains a powerful tool in the transition to a greener and more sustainable energy landscape.